Fabulous Tips About How To Build A Transducer

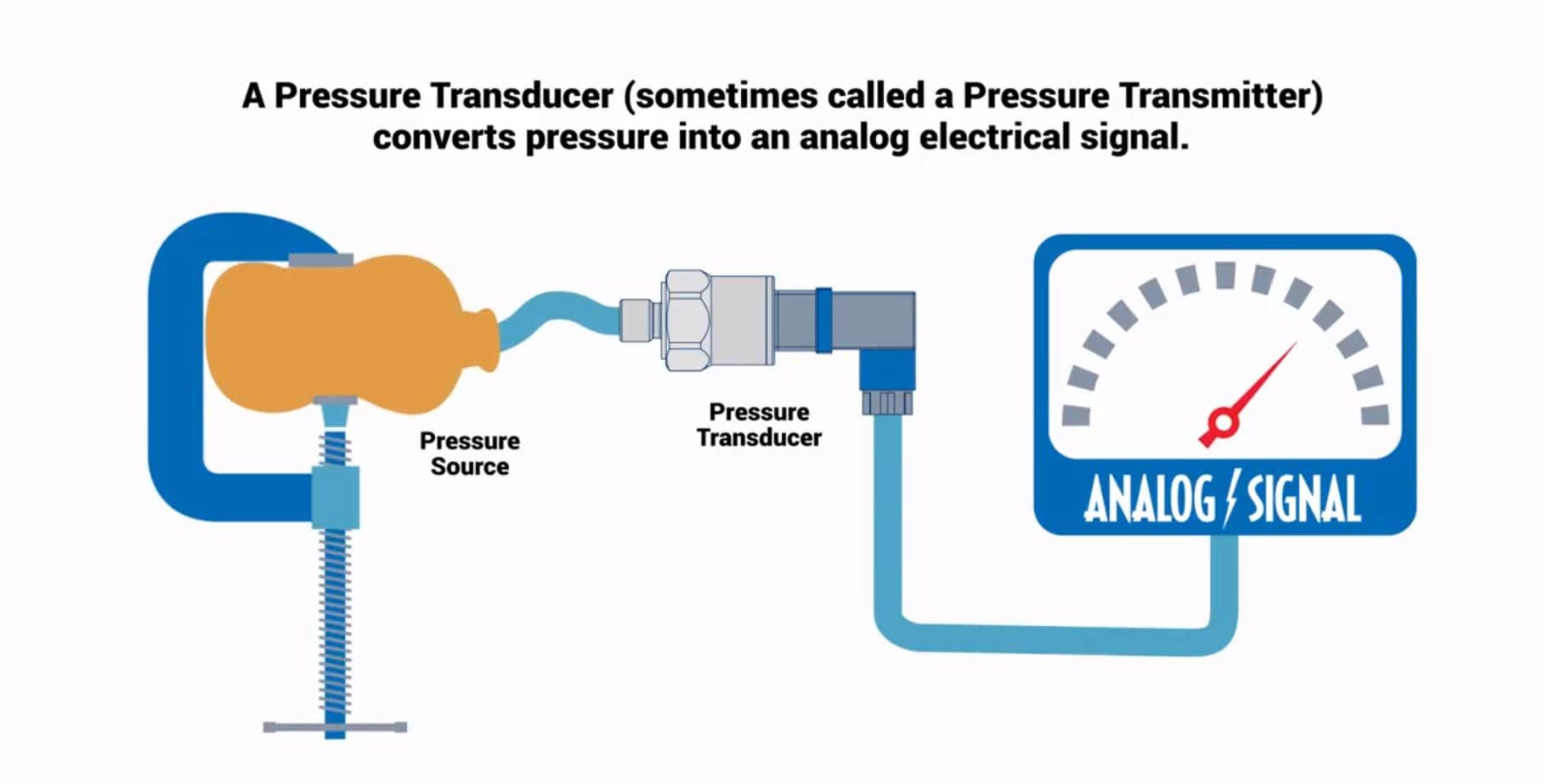

How to build a simple pressure transducer.

How to build a transducer. Well, to begin with at least. Next i reinforced the solder joints with hot glue and. Have a look at our expert talk with angela bäumel and dr.

Apply small amount of solder to iron tip and transfer solder to. These little things are strong for their size. Here is a video on my version of a home made tactile transducer or bass shaker.this construction don't need any epoxy so you will not need long drying time o.

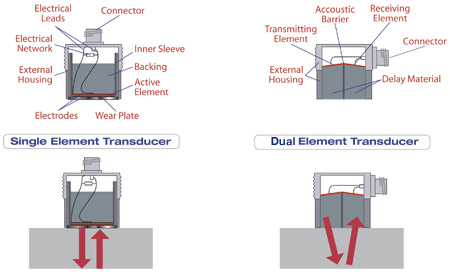

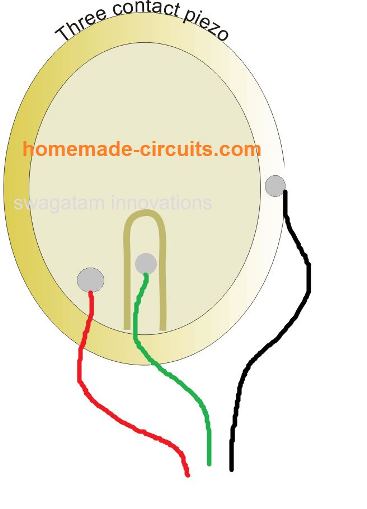

Ultrasonic transducers in that frequency range are not easy to construct since the resonant element (which usually is fabricated from piezoceramic material) must be very thin and very. It has no idea where the data goes. An oscillator driving a pizeo electric cell.

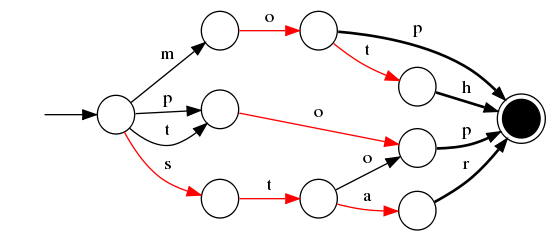

If you need help with anything feel free to contact me. So the first thing i did was to hot glue cardboard inside the lid to make the piezo disc able to lay flat against any surface i attach it to. The transducer only knows that it has to call a designated (and obscure) function with each of it output elements and has to return its result.

1 select a block of wood wide enough to accommodate the head of the transducer and draw an elongatedpear shape. The next step is to consider the. How to build a strain gauge based transducer?

Designing an ultrasonic transducer the first step in designing a transducer is to determine the temperature the device will see over its lifetime. Using barium titanate as the piezoelectric substance, t. 2 drill a hole the diameter and depth of the transducer lobe in the.